2021 High quality Auto Filling Machine - Semi-Auto Grease Squeeze Filling Machine – Higee

2021 High quality Auto Filling Machine - Semi-Auto Grease Squeeze Filling Machine – Higee Detail:

Grease Filling Machine

Description

1. Applicable materials for this model: glass glue; silicone glue; thick mortar materials such as sealant and grease.

2. Applicable packaging container: plastic rigid tube, paper tube and metal aluminum tube, bottle, etc.

3. Operation mode: semi-automatic operation, 1 person to operate filling, 1 person for manual capping, 1 person to operate packaging.

4. Hydraulic discharge machine: suitable for 200L straight standard barrels without ribs. Equipped with energy storage device. System pressure is automatically controlled. The working pressure of the pressing material is stable and adjustable.

5. Quantitative cylinder filling head: touch screen operation, servo motor control precise quantification, touch screen set quantification parameters, quantification accuracy ±1% (calculated according to the actual maximum filling volume), production capacity: 10-25 per minute ( Depends on material viscosity, filling volume and worker proficiency).

Parameters

|

Items |

Parameters |

|

Power supply |

Single phase, 220V, 2.5kw |

|

Filling range |

100-1000ml |

|

Filling speed |

10-25 pcs/minute |

|

Total Weight |

32kg |

|

Dimensions |

600(length)*550(width)*1450(height)mm |

Hydraulic Extruder

Description

1. The sealing device of the pressure plate makes the rubber material well isolated from the air, does not return the material, and wipes the barrel wall without retaining the material.

2. According to the 200L barrel design, the pressure can reach 45T, which is suitable for viscous materials.

3. The hydraulic pressure is independent of the working pressure to ensure stable extrusion pressure and smooth feeding.

Parameters

|

Items |

Parameters |

|

Power supply |

3 phase, 380V, 5.5kw |

|

Pressing plate diameter |

570mm |

|

Lifting height |

1050mm |

|

Lifting method |

Hydraulic |

|

Hydraulic pressure |

0-25Mpa |

|

Diameter of pressure barrel |

Φ570 * 900 mm |

|

Main machine dimension |

700(length)*1500(width)*2650(height)mm |

|

Hydraulic station dimension |

850(length)*550(width)*700(height)mm |

|

Total Weight |

1050kg |

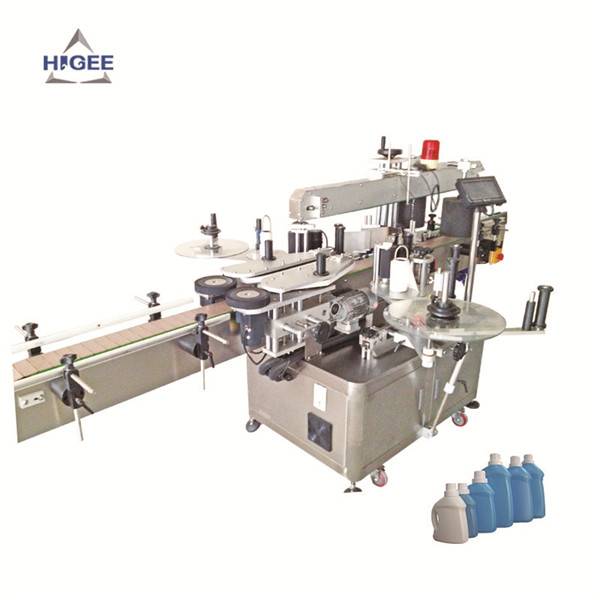

Suitable container

This machine will be suitable for various container like bottles, jars, buckets, hard tubes, etc.

Product detail pictures:

Related Product Guide:

Cooperation

We have been ready to share our knowledge of advertising and marketing worldwide and recommend you suitable products and solutions at most competitive price ranges. So Profi Tools supply you best benefit of money and we're ready to create with each other with 2021 High quality Auto Filling Machine - Semi-Auto Grease Squeeze Filling Machine – Higee , The product will supply to all over the world, such as: Porto, Italy, Toronto, Make sure you genuinely feel free to send us your requirements and we are going to respond for you asap. We now have got a skilled engineering group to serve for your just about every detailed needs. Cost-free samples could be sent to suit your needs personally to understand much more information. In an effort to meet your requires, be sure to seriously feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd objects. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is really our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.