China wholesale Filling Machine Manufacturer - 5L Jerrycan Juice Filling Capping Machine – Higee

China wholesale Filling Machine Manufacturer - 5L Jerrycan Juice Filling Capping Machine – Higee Detail:

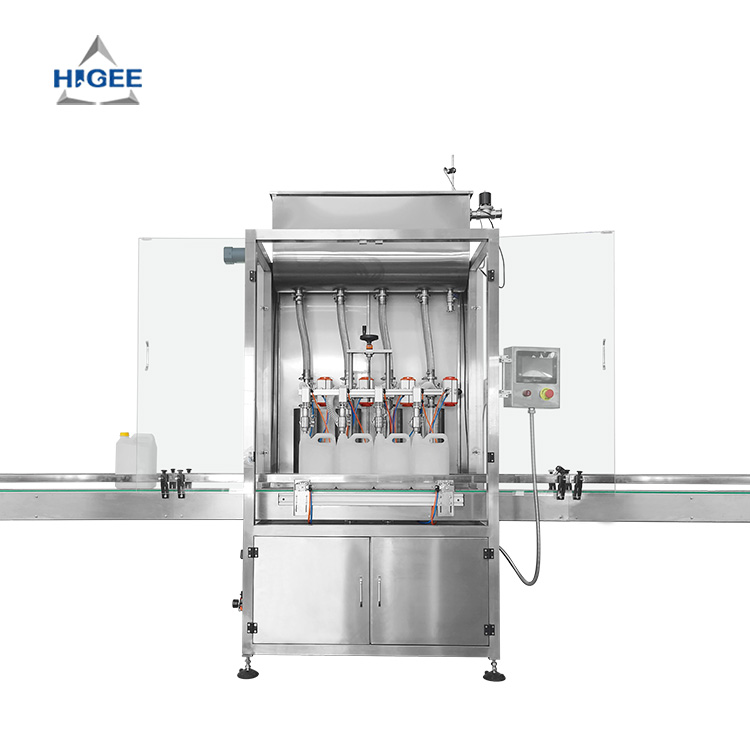

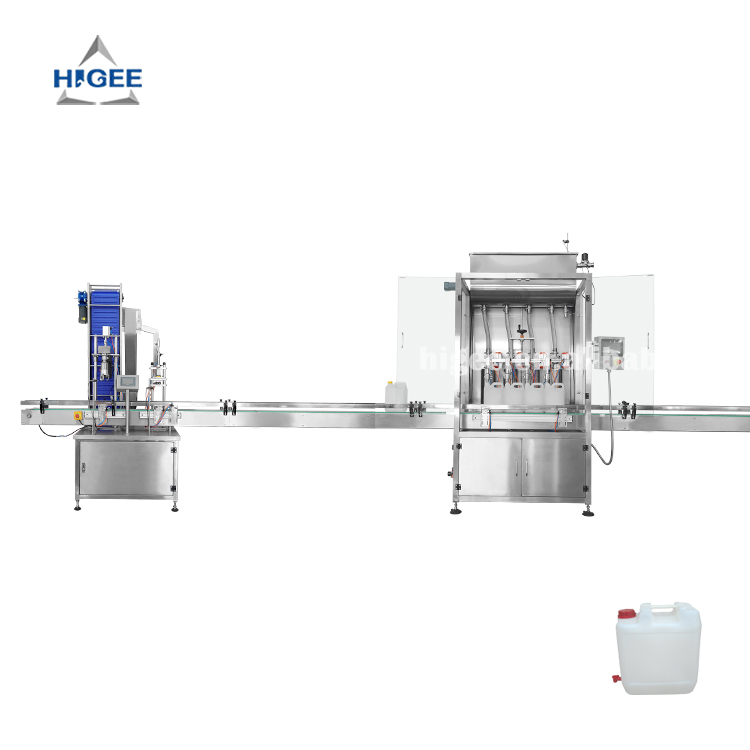

5L Jerrycan Juice Filling Capping Machine Line

5L Bottle Juice Filling Machine with Feeding Stirring Hopper

Description

This automatic linear filling machine is designed for juice filling in 5L jerrycan, the juice is with granules in it.

Technical parameter

|

Items |

Parameters |

|

Filling nozzle |

4 |

|

Hopper function |

Automatic liquid level detection, automatic feeding, stirring, heating |

|

Filling volume |

Up to 5L (can be customized) |

|

Capacity |

ABT. 5-20BPM for 5L |

|

Air source |

0.6-0.8MPa |

|

Power supply |

220V/50Hz, 2.5kw |

|

Total Weight |

600kg |

|

Dimensions |

2400*1500*1800mm |

Details

- 4 filling nozzles: Filling quantity can be set in touch screen.

- With slide device: the users can adjust the position of filling nozzles freely to fit in different bottle sizes.

- The cylinder is designed and arranged inside the machine, making the machine simple and beautiful.

- With upper hopper: client can choose to add stirring function and/or heating function, suitable for thick liquid or liquid with granules.

- Hopper can be connected with storage tank.

- With automatic liquid level control function, can detect low liquid level and feed the liquid automatically, which saves manpower.

- With waste water flow out interface, which is convenient to discharge the waste water after cleaning.

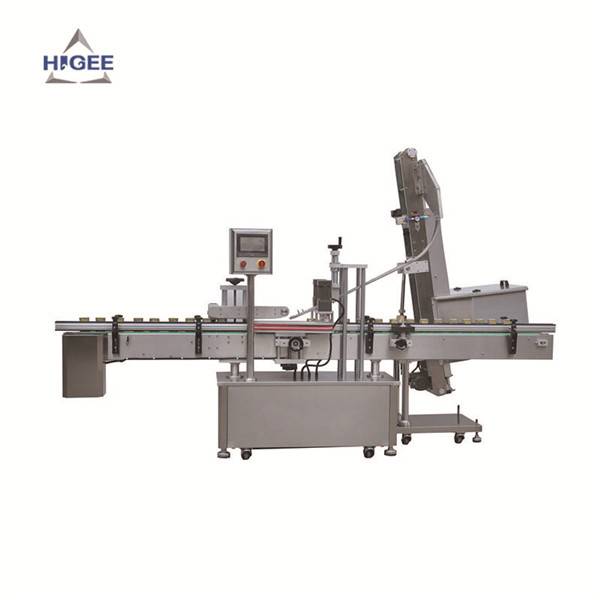

Automatic Jerrycan Capping Machine with Cap Elevator

Description

This automatic capping machine is suitable for jerrycan capping with screw type ROPP cap. The machine is equipped with an automatic cap feeding machine – cap elevator. Can achieve fully automatic cap arranging, feeding and capping.

Technical parameter

|

Items |

Parameters |

|

Capping head |

Claw type |

|

Feeding type |

cap elevator |

|

Capacity |

ABT. 1000-2000BPH |

|

Air source |

0.6-0.8MPa |

|

Power supply |

220V/50Hz, 1kw |

|

Total Weight |

400kg |

|

Dimensions |

2000*1500*1800mm |

Details

Product

Related Product

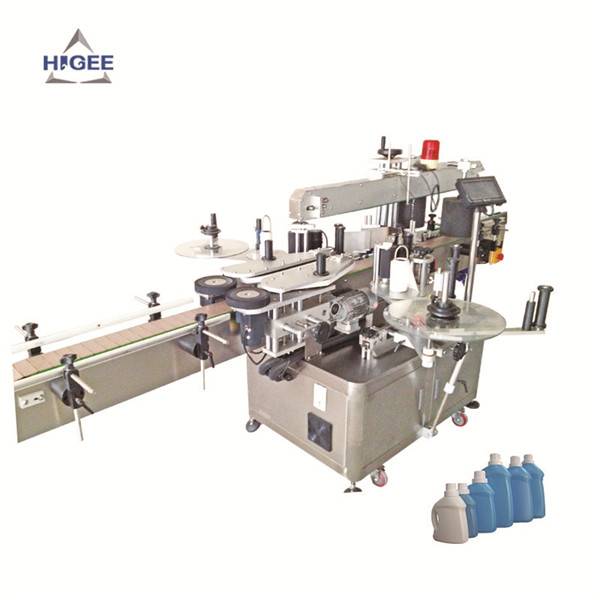

*Higee Double side labeling machine

Contact Higee Machinery to know more details!

Product detail pictures:

Related Product Guide:

Cooperation

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for China wholesale Filling Machine Manufacturer - 5L Jerrycan Juice Filling Capping Machine – Higee , The product will supply to all over the world, such as: Slovenia, Oman, Argentina, Our team knows well the market demands in different countries, and is capable of supplying suitable quality products at the best prices to different markets. Our company has already set up a professional, creative and responsible team to develop clients with the multi-win principle.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.