Factory wholesale Powder Filling Machine - Vertical Ampoule Filling and Sealing Machine – Higee

Factory wholesale Powder Filling Machine - Vertical Ampoule Filling and Sealing Machine – Higee Detail:

Vertical Ampoule Filling Machine

Description

The machine is simple and compacts structure, smooth and reliable operation convenient operation and adjustment, completer functions, if there is ampoules absent at filling station, an automatic stop-filling device can avoid the leakage of liquid solution, the advanced peristaltic pump is used for metering filling, which has the advantages of high metering accuracy, convenient cleaning, does not pollute solution and no drop and leakage from needle, the filling volume adjustment is controlled by PLC, which is easy to operate.

Features

- compact structure, occupy less space, suitable for small ampules and milti-specification production and trial.

- We use imported peristaltic pump, it has high filling accuracy, suitable for many volume filling demand.

- The conjunction between tabletop and support column that above table was designed as chamfer type, tidy and beautiful, no blind corner of cleaning

- Adopt mesh-belt and spiral screw to feeding ampoules, avoid the slim ampoule falling over.

- This machine includes ampoule in-feeding, N2 filling, liquid filling, sealing stations.

- The machine has one-key calibration function for filling volume, easy and visualized setting.

- The filling needle is elevated by linear guide rail, ensure needle can accurate insert into ampoule mouth, won’t bump damage ampoule, avoid occur charring spot while melt sealing.

- Can be installed with ORABS/CRABS grade LAF purifying hood to realize no interrupt production inside equipment (option)

- Can be equipped with online LAF monitoring system, includes the LAF speed/dust particle quantity /planktonic and sendi-metation bacteria/microbe etc, to meet GMP manufacturer requirements (option)

- We can custom design equipment according to user production requirements

Technical parameter

|

Items |

Parameters |

|

Model |

HG-1 |

|

Application for |

1-20ml ampoules |

|

Productivity |

12000-7000 bottles per hour for 1ml |

|

Filling station |

1 pcs |

|

Filling method |

Ceramic pump /peristaltic pump |

|

Filling accuracy |

≤ ±0.5% |

|

Sealing qualification rate |

99.5% |

|

Fuel Consumption |

1-2 M3/h,0.1 Mpa |

|

Oxygen consumption |

0.1-1M3/h, 0.1 Mpa |

|

Power supply |

380V/ 50hz 3 phase 1kw |

|

Machine size |

1100*1000*2400mm |

|

Weight |

550kg |

Details

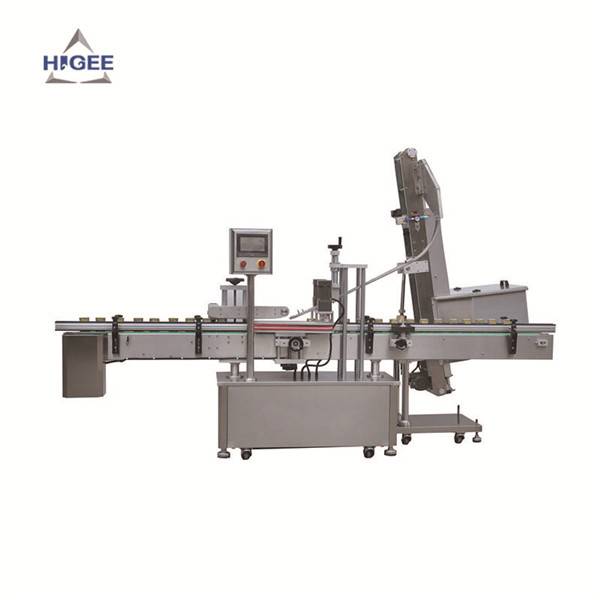

HAW Series Labeling Machine

HAW200/300 Economical Horizontal Labeling Machine

HAW600 High Speed Horizontal Labeling Machine

Suitable products

Product detail pictures:

Related Product Guide:

Cooperation

Bear "Customer first, Quality first" in mind, we work closely with our customers and provide them with efficient and professional services for Factory wholesale Powder Filling Machine - Vertical Ampoule Filling and Sealing Machine – Higee , The product will supply to all over the world, such as: Panama, Colombia, Gabon, Our products are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.