Manufacturer for Cup Filling Machine - 3000BPH Glass Bottle Juice Filling Line – Higee

Manufacturer for Cup Filling Machine - 3000BPH Glass Bottle Juice Filling Line – Higee Detail:

Features

1. This machine has compact structure, complete control system, convenient operation, high degree of automation and low labor intensity.

2. The parts in contact with the materials are made of food-grade high-quality stainless steel, which is corrosion-resistant and easy to clean.

3. The bottle washing system adopts the company’s original flip bottle clamp, the bottle clamp is stuck on the bottleneck,

4. The washing machine of the three-in-one filling unit uses special special high-efficiency spray nozzles exclusively in the country. The washing water is sprayed at a set angle and can be washed to any part of the inner wall of the bottle, thoroughly washing and saving water for washing the bottle.

5. It adopts high-efficiency cap sorting system, with perfect cap cover technology and protection device; cap-dropping guide rail is equipped with anti-cap passing and anti-cap removal mechanism; with bottle cap detection mechanism, used to control the start and stop of capping device.

6. The filling valve of the three-in-one filling unit adopts German technology and adopts high-precision, high-speed quantitative filling valve for automatic filling. The liquid level is accurate and there is no liquid loss. When there is no bottle, the valve is closed in time to prevent liquid loss and ensure excellent Filling quality; cooperate with the mixer to realize the functions of disinfection cycle, open valve drainage and cleaning. The filling volume is accurate and the failure rate is low, which provides a reliable hardware guarantee for ensuring product quality and reducing losses.

7. Equipped with CIP cleaning system, the pipes in contact with materials are all configured with 316L stainless steel.

8. The capping machine of the three-in-one filling unit is designed and manufactured by introducing the design technology of the French capping machine, which makes the equipment run smoothly and the capping is reliable, and guarantees the qualified rate of the product from the core equipment of the filling unit.

9. The transmission system adopts gear transmission. The transmission gear adopts a cross arrangement of steel gears and nylon gears, which is not easy to wear and has low noise.

10. Equipped with a complete overload protection device, which can effectively protect the safety of the machine and the operator.

11. The operation of the whole machine adopts advanced touch screen control, and the production speed, shift output count, fault category, fault occurrence point, etc. are all displayed on the screen. And it can automatically count the time of occurrence of failure, failure category and other information.

12. Exclusive use of stainless steel countertop through-hole tensile structure (reverse pull technology), with O-ring seals, so that all the bearing seats and support shafts on the countertop may reduce leakage to zero.

Parameters

|

Items |

Parameters |

|

Production capacity |

3000BPH (250ml) |

|

Washing head |

14 |

|

Filling head |

12 |

|

Capping head |

5 |

|

Air pressure |

0.7 MPa |

|

Air consumption |

0.3M3/min |

|

Filling method |

Negative pressure filling |

|

Power |

3 phase 380V, 50hz, 3KW |

|

Machine Weight |

3000kg |

|

Machine Size L × W × H (mm) |

2360×1770×2700mm |

Details

1, Washing Filling Part

2, Capping&Conveyor

3, Spray cooling system

4, Bottle blow dryer

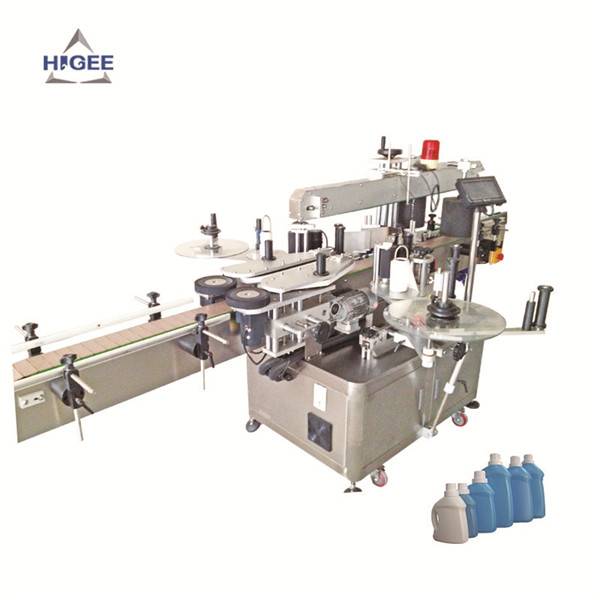

5, Labeling machine

6, Ink jet printer or Laser printer

Product detail pictures:

Related Product Guide:

Cooperation

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for Manufacturer for Cup Filling Machine - 3000BPH Glass Bottle Juice Filling Line – Higee , The product will supply to all over the world, such as: Hamburg, New Orleans, Greek, we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.