High Quality Filling Equipment - Automatic Glycerin Filling Capping Labeling Machine – Higee

High Quality Filling Equipment - Automatic Glycerin Filling Capping Labeling Machine – Higee Detail:

Main process:

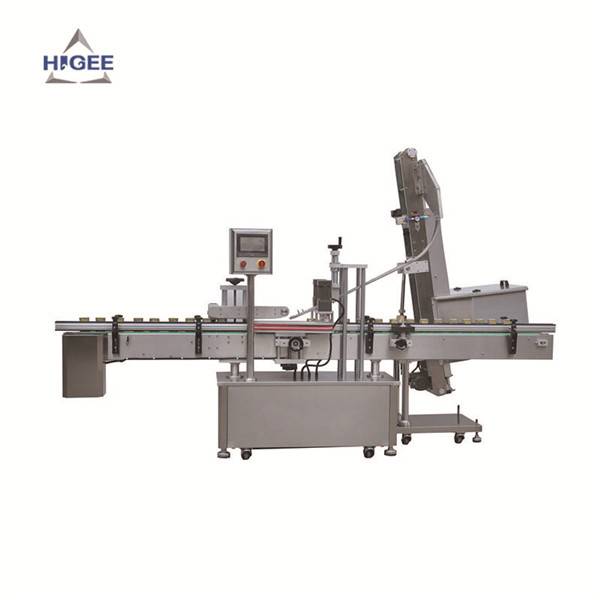

Bottle feeding table(Rotary type) – Liquid filling – automatic cap loader – automatic capping – round bottle labeling machine – Shrink labeling machine – output.

Bottle Rotary Feeding Machine

Bottle Rotary Feeding Machine

Description

This machine integrates the functions of automatic bottle feeding, automatic positioning, filling, stoppering, and capping. It is widely used in pharmaceutical, biological, daily chemical, chemical and other industries.

Features

1, With touch screen & PLC control, with functions such as no bottle no filling, no bottle no capping. Variable frequency speed regulation, continuously adjustable operating speed.

2, Overload protection and alarm prompt function, more safe and reliable.

3, Intelligent control of filling volume: the touch screen directly inputs the filling volume, and the filling volume is automatically calibrated. It is very convenient to switch between different specifications and adjust the loading volume, and there is no requirement for the level of the operator. Avoid the trouble of traditional test while adjusting.

4, Mechanical claw capping, including torque detection and capping unqualified alarm prompt function, the capping torque can be set on the touch screen, which is convenient and quick, and can greatly improve the capping pass rate and capping quality.

Technical parameter

|

Items |

Parameters |

|

Filling nozzle |

2 |

|

Capping head |

2 |

|

Filling pump |

Peristaltic pump |

|

Filling volume |

10ml (can be customized) |

|

Capacity |

50 (bottles/min) |

|

Air source |

0.6-0.8MPa |

|

Power supply |

220V/50Hz, 2.5kw |

|

Total Weight |

800kg |

|

Dimensions |

2200×1700×1800mm |

Details

Round Bottle Sticker Labeling Machine

Shrink Sleeve Labeling Machine Unit

Features

-Single shrink label feeding tray, microcomputer automatic control;

-Automatic detection, automatic positioning;

-Fast label change, labor-saving, accurate cutting position.

Technical Parameters

|

Items |

Parameters |

|

Filling nozzle |

2 |

|

Capping head |

2 |

|

Filling pump |

Peristaltic pump |

|

Filling volume |

10ml (can be customized) |

|

Capacity |

50 (bottles/min) |

|

Air source |

0.6-0.8MPa |

|

Power supply |

220V/50Hz, 2.5kw |

|

Total Weight |

800kg |

|

Dimensions |

2200×1700×1800mm |

|

Items |

Parameters |

|

Filling nozzle |

2 |

|

Capping head |

2 |

|

Filling pump |

Peristaltic pump |

|

Filling volume |

10ml (can be customized) |

|

Capacity |

50 (bottles/min) |

|

Air source |

0.6-0.8MPa |

|

Power supply |

220V/50Hz, 2.5kw |

|

Total Weight |

800kg |

|

Dimensions |

2200×1700×1800mm |

Suitable products

*Example of suitable products

Product detail pictures:

Related Product Guide:

Cooperation

Our products are broadly regarded and reliable by end users and can meet up with constantly transforming financial and social requires of High Quality Filling Equipment - Automatic Glycerin Filling Capping Labeling Machine – Higee , The product will supply to all over the world, such as: Swiss, Las Vegas, France, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.