PET Bottle Juice Hot Filling Machine

Compete PET Bottle Juice Hot Filling Machine 4 in 1 Monoblock Production Line

Features:

The machine elements that contact with the liquid is made of high quality stainless steel, The critical components are made by numerically-controlled machine tool, and the whole machine condition is under detection by photoelectric sensor. It is with advantages of high automation, easy operation, good abrasive resistance, high stability, low failure rate, etc.

We can also equip the drink production line with water treatment equipment, pre-treatment mixer equipment system, and the packing system including shrink sleeve labeling machine, shrink packing machine etc.as one complete line.

1. Air conveyor

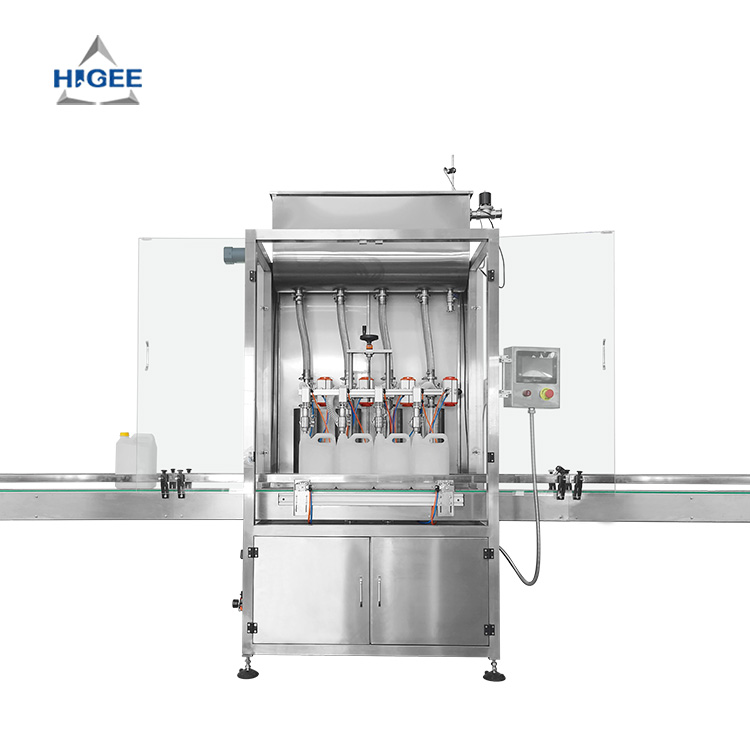

2.Juice Filling and Packing System

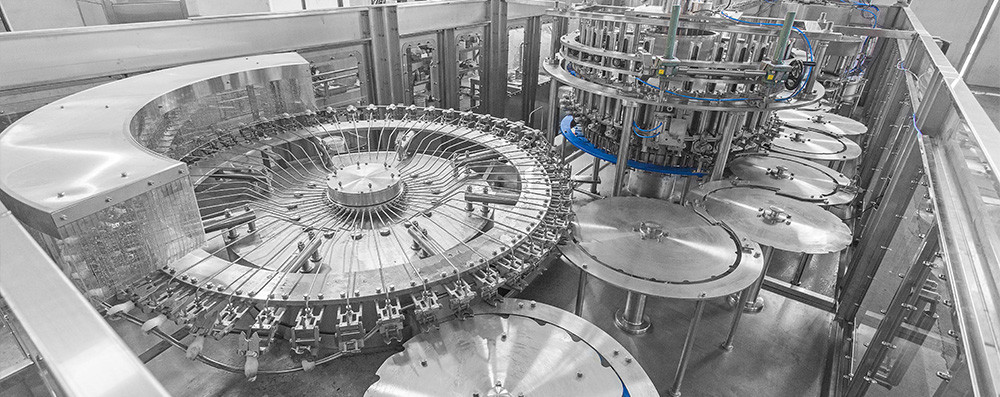

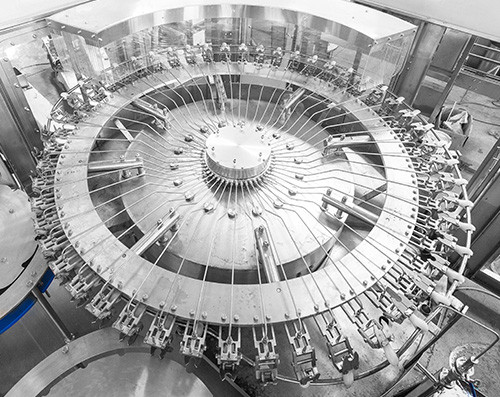

General description

RXGF series juice hot filling machine integrates bottle washing, water filling and capping into one monoblock, and the three processes are carried out full automatically. It is used in the hot filling of juice and tea beverage. It is equipped with perfect temperature control system, reverse-flow system, automatic cleaning system and control program. Each machine element that contacts with the liquid is made of high quality stainless steel and food-grade rubber.

Rinsing Part

● All stainless steel rinser heads, water spray style inject design, more save water consumption & more clean.

● Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

● stainless steel washing pumps

Filling Part

● High precision filling nozzle, PLC variable signal control, ensure high filling precision

● Gravity filling, & filling smoothly & steadily

● All stainless steel contact parts & liquid tank, fine polish, easy to clean

● No bottle no filling

Capping Part

● Place & capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

● All 304 stainless steel construction

● No bottle no capping and Automatic stop when lack of bottle

|

Model |

Capacity/500ml |

Bottle size |

|

RXGF 8- 8-3 |

1000-2000bph |

200-1500ml |

|

RXGF 14-12-5 |

3000-4000bph |

200-2000ml |

|

RXGF 16-16-5 |

5000-6000bph |

200-2000ml |

|

RXGF 24-24-8 |

8000-10000bph |

200-2000ml |

|

RXGF 32-32-8 |

10000-12000bph |

200-2000ml |

|

RXGF 40-40-10 |

13000-15000bph |

200-2000ml |

|

RXGF 50-50-15 |

15000-18000bph |

200-2000ml |

3.Bottle Turn Up Sterilizer

4.Spray Sterilizer